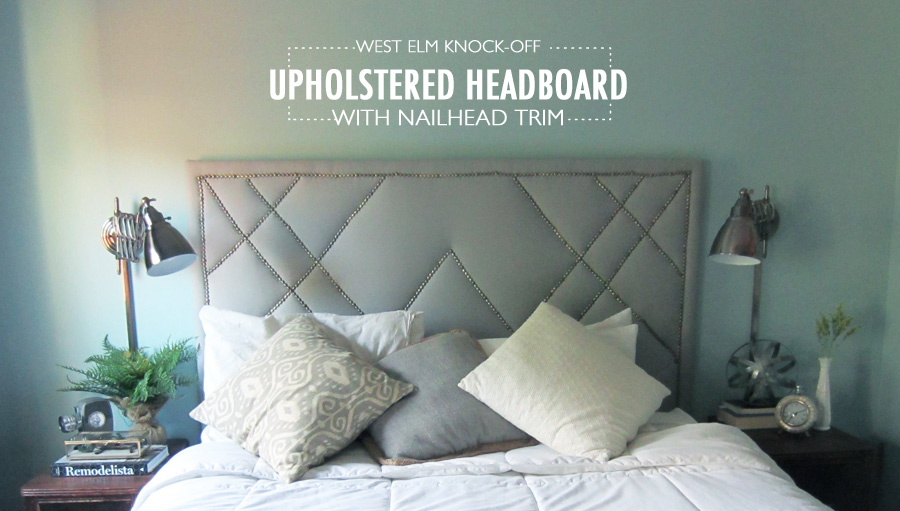

When I started telling my friends that we bought a house, the most common reaction was, “Whoa – you guys are grown ups now.” Nay, friends! I didn't become a grown up until I got a real headboard and solid wood bed frame (that you can look under and not find my old ballet shoes and Pink Floyd tees).

I’d been eying this beauty from West Elm for a while, but like I said – I wasn’t quite a grown up (or fabulously wealthy) yet so I just didn't feel OK forking out $600 for a headboard or $350 for this bed frame. It's no wonder my generation still uses metal bed frames that you have to hide under a bedskirt. You can pay a grand after taxes to get the bed of your dreams, or you can pay $10 to the grad student on Craigslist for a bed that serves the same purpose!

What is a bed frame & headboard other than some wood screwed together, really?! (I learned it’s a little more than that ... foreshadowing ... ) So I decided we'd build that dream bed for less than $200, or my name isn’t Chloe Joy. I took to Pinterest, which is in no short supply of upholstered headboard tutorials – the hard part is choosing which one to follow. They all look something like this:

1. Cut wood , 2. Cover with something cushiony , 3. Add fabric

Other things to consider include: desired shape, cushion material (foam or batting, or foam + batting), type of fabric, decorative details (like tufts or nailhead trim), and installation method.

Here's what I used:

• 1 sheet of MDF – 4 ft. x 8ft. x 5/8" thick board cut to 63 inches wide x 40 inches tall – $35

• 2 in. x 4 in. x 6 ft. – $3

• 1.5 in. wood screws – $7

• 3 in. wood screws – $9

• 10 yards of polyester batting – $15

• 2 yards of duck canvas fabric – $14

• Staple gun & staples – $21

• 15 yards of nailhead trim (in antique gold finish) – $45

• Rubber mallet (or a jerry-rigged version – more on that later)

Step 1: Tape your desired shape on the wall

The West Elm headboard I chose is a simple rectangle – hardly a coincidence. I knew it would make my life easier when building it, and it had the added bonuses of being a little more masculine and unlikely to go out of style any time soon. Even with a simple silhouette, it helped to outline the shape on the wall above my bed with painters tape. This allowed me to fiddle with the dimensions by moving the tape up or down until I felt like the proportions were right. I relied on the West Elm specifications for queen-sized headboards to determine it should be 63 inches wide, which leaves an inch or so of overhang on either side of your mattress. As for the height, Eli and I took turns sitting on the bed and pretending to lean back on our "headboard" to make sure it was a comfortable height for both tall and not so tall persons to rest their heads.

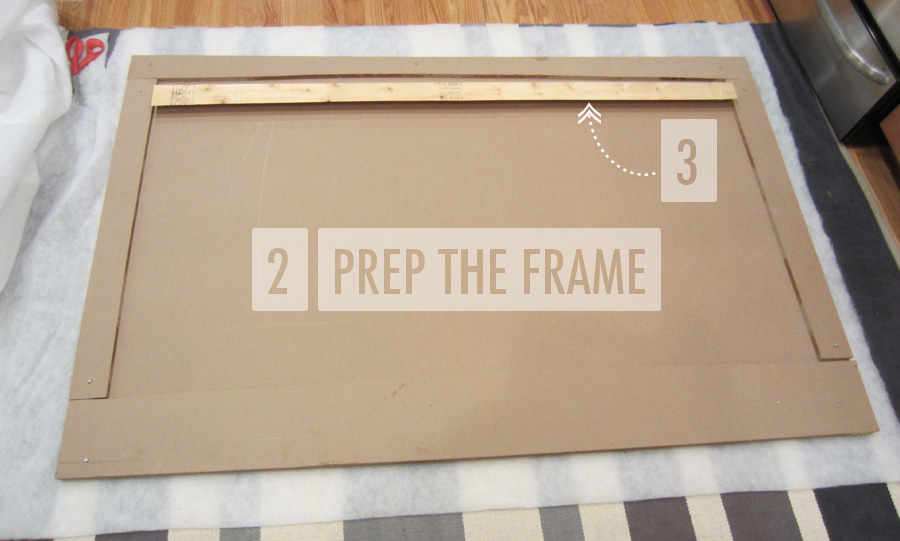

Step 2: Create the frame

I picked up a 4 ft. x 8 ft. sheet of MDF from Home Depot and had them cut it to be 63 in. wide. If I'd been smarter I would have written down both the width AND height and had the guys cut it to spec. Alas, I had to pull out the circular saw and sawhorses to finish my cuts when I got home. From the leftovers, I cut 4 additional pieces – one for each edge of the frame – that I then screwed to the main board with 1.5 in. wood screws, making the outside edges flush. This gives the illusion of a thicker, more substantial hunk o' wood when you catch a side view of the headboard but it doesn't add much extra weight or $$.

Step 3: Prep your hanging mechanism

I decided we would hang this headboard on the wall with a French cleat instead of trying to attach it to the bed frame. Gotta come clean here – I had no idea what a french cleat was before this project. Turns out it's a rudimentary way to hang heavy things, like cabinets or headboards. We cut a 2 x 4 x 6 down to 5 ft. long – a few inches shy of our headboard's width – and then halved it longways at a 45 degree angle. Our circular saw has an adjustable blade that can be tilted to make cuts on an angle. We carefully cut this angle down the entire length of the board. This gives us two long pieces of wood that fit together like a puzzle....or like a french cleat. We attached one half to the back of the frame (same side as the other scrap pieces) and the other half would be attached to the wall later. Notice that the 2 x 4 comes out further than edge pieces of MDF. If you decide you want to make your headboard much thicker than mine, just make sure that the 2 x 4 will reach the wall before the back of the headboard does when you go to hang it. Our MDF was 5/8 in. thick, so we used 1.5 in. long wood screws and made sure that the pizza slice edge pointed down and away from the frame. I tried to make sure this board was level, but it was tricky because the 2 x 4 wasn't perfectly straight to begin with and I knew I could make small adjustments when positioning the other piece on the wall.

Step 4: Add batting

Many tutorials suggest using foam for cushion, which is certainly the higher quality choice, but I was going for cost effectiveness here. A big piece of thick, high quality foam could have cost anywhere from $60 to $160, whereas this large roll of batting only cost me $15. To compensate, I used six layers of it. You heard me right – SIX! I rolled the first layer out on a clean rug, laid the frame facing down, and wrapped the batting around the edges, stapling it to the back. It gets harder with each subsequent layer to find space to staple...and harder to staple through all the batting into the actual frame. Hindsight is 20/20, so I suggest stapling your first layer pretty close to the frame's edge (meaning there's very little overlap on the back), trimming the excess, and making each additional layer reach a little further than the last, with a slightly bigger overlap on the back of the frame. Make sure the batting is pulled taut across the front of the frame to create a smooth surface – check the front occasionally for bunching.

Corners get especially bogged down with batting on the back, so I ended up cutting into them at a 45 degree angle to thin most of it out.

Step 5: Attach your fabric

The West Elm headboard is in a really beautiful dark gray linen weave. I chose a much cheaper, readily available alternative: duck canvas. I only needed 2 yards and it was on sale for $6.99/yd at Joanns. This was my first attempt at making a headboard, so the durability and affordability of the fabric gave me piece of mind that if I totally botched it I could start over without wasting a ton of money. It all worked out, though and I'm still perfectly happy with how the canvas looks and feels.

The rug I'd been using as my work surface was clean, but I layered a freshly laundered sheet over it to feel 100% confident I wouldn't be getting shmutz on my new headboard. Then I laid out the canvas and actually ironed it on the floor. You really don't want to be looking at the same wrinkle above your bed for the rest of eternity.

I followed the same process for attaching the fabric that I did with the batting – lay the frame facing down, pull the fabric around the edges and staple to the back. That makes it sound easy, so let me clear my conscience here and tell you it was NOT. Eli had gone out of town by this time, and I was too impatient and cocky to wait for him – figuring I was plenty strong and skilled to do it on my own. Luckily I was right (Girl Power!) but it was not as easy as the tutorials made it sound. You really have to be careful on this step – making sure to keep your fabric straight and pull it really taut, so that you don't get wrinkles or bagginess. I struggled to pull the fabric hard with one hand, lift the headboard with the other to check all was well and good on the front side, lay it down again without messing it up, keep pulling the fabric with that one hand and fire the staple gun with the other. Sure, it's fun to impress yourself, but it's more fun to have a friend help so you don't have to shout obscenities to an empty room.

I started by stapling in the middle of one edge, then hopping over to the opposite (parallel) edge to pull the canvas taut and staple in the middle again. Then I'd work my way out from the middle on those two sides, hopping back and forth, before repeating the process on the remaining sides.

When I got to a corner, I stapled one edge completely smooth, trimmed the excess and then carefully folded the other side over it to create a nice smooth appearance from the front, top and side. Luckily no one will see the hack job on the back ;)

Step 6: Install nailhead trim

If you want, you could stop here and have a totally acceptable upholstered headboard. I would have if West Elm's geometric nailhead trim hadn't hypnotized me. I ventured ever so slightly from their pattern, sketching my own on paper before laying it out on the headboard.

I ordered 15 yards of Dritz Home nailhead trim in antique gold off Amazon, but only used 12 or so. This stuff is amazing, because as you can see in the top picture, it's just a long strand of metal that looks like individual nailheads. In reality, you only have to bang in a decorative nail every 6th one or so. I'm all for things that look more complex than they are. It's highly recommended that you use a rubber mallet for the banging, so you don't dent or scratch your pretty nailheads. I, however, did not see a rubber mallet at my local store and was still feeling antsy/impatient/cheap. Instead I just jerry-rigged a "gentle hammer" by stuffing a big wad of batting on the head, covering it with a canvas scrap and tying it together with a rubber band. #MacGyver

I really made a rookie mistake on this step (but I later forgave myself since I was in fact a rookie). I started hammering in the nailhead trim along the top edge first. Do yourself a favor and start somewhere that will be covered by your mattress or pillows or pretty much anywhere except the most visible spot. It took me a while to get the hang of the trim, so my lines were wobbly to begin with. I considered removing them and starting over, but that would have damaged the fabric so I just forged ahead. I didn't get the factory-straight lines I was hoping for, but I just try to ignore and/or embrace the imperfections.

Step 7: Hang the headboard

To hang the headboard level, we taped the second half of the cleat to the first half and held the headboard up to the height we'd marked with our tape. One of us (Eli) kept holding it in place while the other (me) marked where the cleat should go on the wall. We did it this way because of the less-than-perfectly-straight nature of the 2 x 4. We didn't want to hang the board level and then find the headboard was all wonky.

We marked our studs, drilled pilot holes through the 2 x 4, and then secured it with 3 in. wood screws. Our studs are 16" apart and our 2 x 4 was 60" long, so we were able to attach it to 3 studs. Feeling confident in that sturdiness, we hung the headboard on the cleat, et voila!

We are very happy with our new headboard! Especially since it only cost us about $150 and approximately 12 hours.

You guys know I'm always gonna keep it real with you. When I finished hammering the last nail, my arms were tired, my back was sore, my fingers were raw, and I realized why it costs several hundred dollars to buy this from a store. $600 still feels very steep to me, but now I could see myself paying $350 or so for an intricate headboard with perfectly straight lines. That being said, it would have taken me another year or so to pull the trigger and my bedroom is feelin' much more sophisticated now. In a future post, I'll finish the bed saga and show you how we got a solid wood bed frame for $FREE.99 !

Have you ever built an upholstered headboard? Was it easier or harder than you expected? Anything you would have done differently?